Back Pull Out Principle

True back-pull-out feature allows inspection/repair of the rotating cartridge without disturbing the piping or coupling alignment, which will give you:

- Reduced downtime costs

- Reduced labor costs

- Spares optimization

ROTAN® pumps are made with a ”back pull out” system!

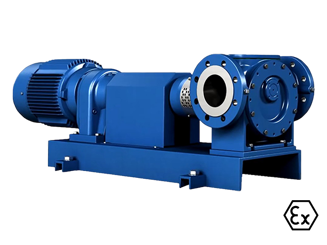

This means that a pump, delivered on a base plate, with a spacer coupling, connecting gear or motor to the pump, can be serviced without breaking any pipe connections or moving the motor/gearbox.

Just by taking out the spacer in the coupling you have access to dismount the total rear end of the pump.

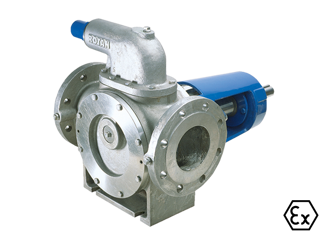

The ROTAN® Uptime Cartridge can be mounted in a matter of minutes, thus minimizing the downtime and the cost of lost production. Further more you have the advantage that the Cartridge which has to be serviced can have new/ serviced components mounted/repaired without having to pay extra for fast delivery.

As an example you could have a pump with tungsten bearings and a shaft seal with SIC/SIC faces.

The front cover can always be serviced without disturbing pipes or motor/gearbox. Normally the tungsten bearings last for two or three sets of “wear parts”, meaning that the bearings can be re-mounted in the serviced cartridge and some of the seals can be cleaned, re-lapped and get new O-rings (with full factory warranty).

In this way you save money for expensive parts, get less downtime and loss of production.

The ROTAN® mag-drive pumps can also be delivered with a free shaft end and a spacer coupling. Having this construction, you are also able to enjoy all the advantages of an Uptime Cartridge with the mag-drive pumps.

With the ROTAN® Uptime Cartridges you have lots of time to service the cartridges and thus the repair staff can service the cartridges at a time where the work is not so hectic or you could let the work be done at one of ROTAN® ’s workshops