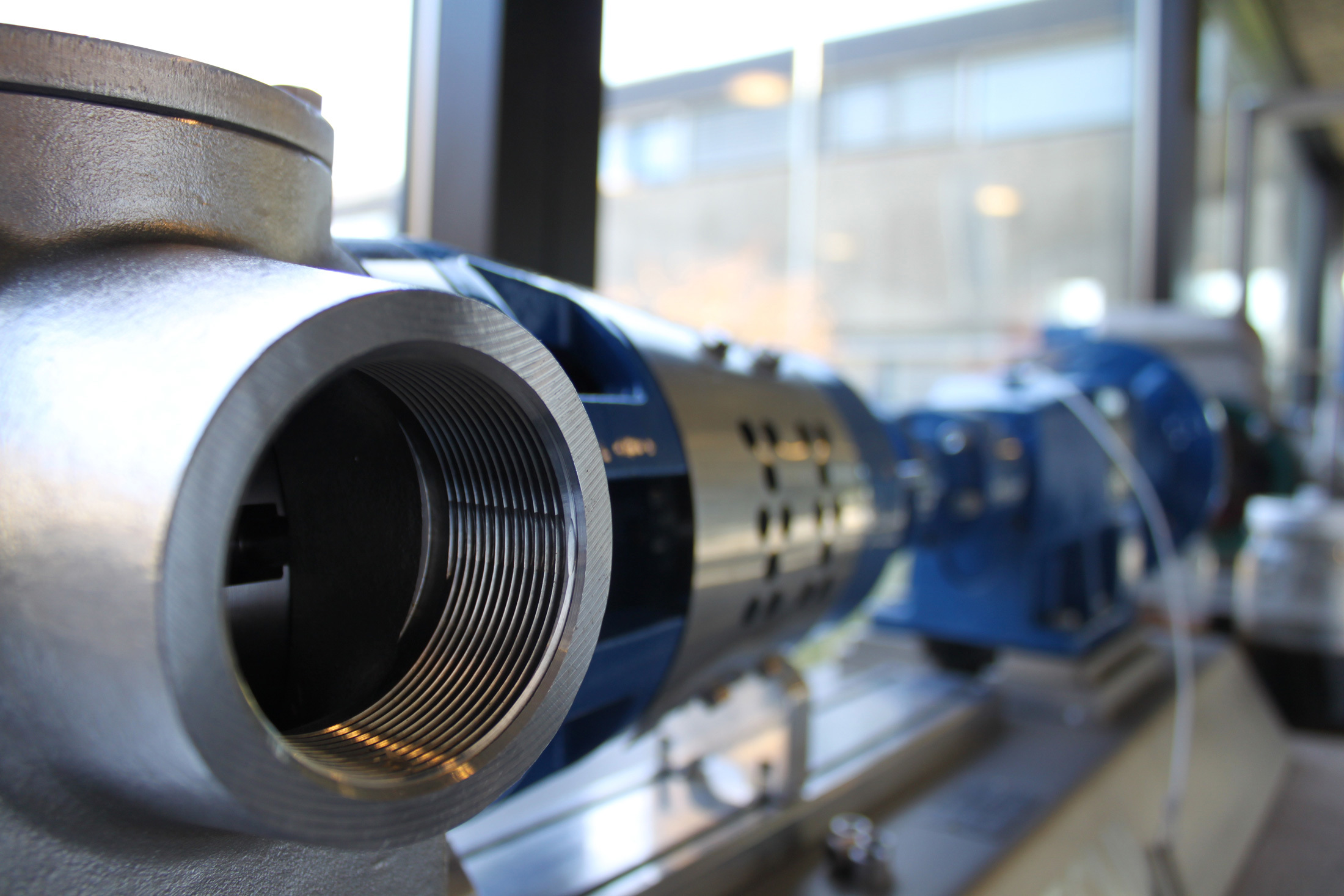

Internal Gear Pumps - ROTAN®

What is an internal gear pump?

Definition

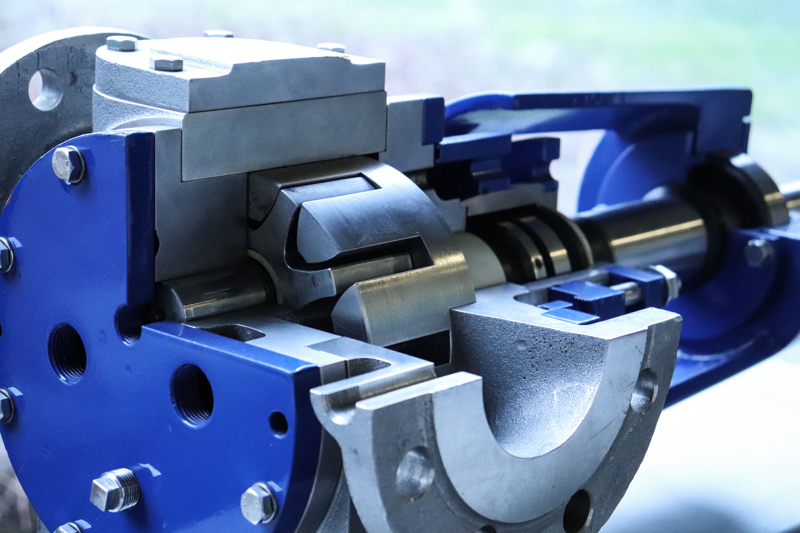

An internal gear pump is a positive displacement pump designed to move liquids using two interlocking gears - one internal (rotor) and one external (idler) - separated by a crescent-shaped divider. It delivers a smooth, non-pulsing flow that makes it ideal for both thin and highly viscous fluids.

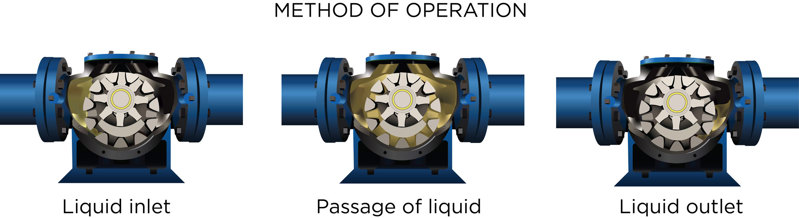

How it works

The rotor gear connects directly to the drive shaft and rotates inside the idler gear, which is mounted off-center. As the gears turn, liquid is drawn into the cavities between the teeth and the crescent. The crescent acts as a divider, separating the suction and discharge zones and minimizing slippage.

This configuration:

- Enables gentle liquid handling, ideal for shear-sensitive media

-

Produces low noise due to continuous flow

-

Delivers high volumetric efficiency, especially at higher viscosities

-

Supports bidirectional pumping by reversing motor direction

The modular concept

The unique, modular concept of ROTAN® pumps is generally recognized as the most advanced internal gear pump design available today.

This means that superior self-priming capability and gentle liquid handling are achieved, and also that highly viscous liquids can be pumped.

Why choose a ROTAN® internal gear pump?

ROTAN® internal gear pumps are engineered for long-term performance in demanding industrial environments. Whether you need to move high-viscosity fluids, protect against leakage, or maintain uptime across complex systems, the ROTAN® design delivers efficient, reliable flow. Built around modular principles and tested to industry standards, these pumps offer both technical precision and operational flexibility.

Key advantages include:

- Smooth, pulse-free flow for consistent process performance

-

Self-priming operation with excellent suction characteristics

-

Low internal velocity to reduce shear and wear

-

Reversible flow direction for flexible system design

-

Hydrostatic testing of every unit before delivery

-

Certified versions for ATEX zones and API 676 compliance

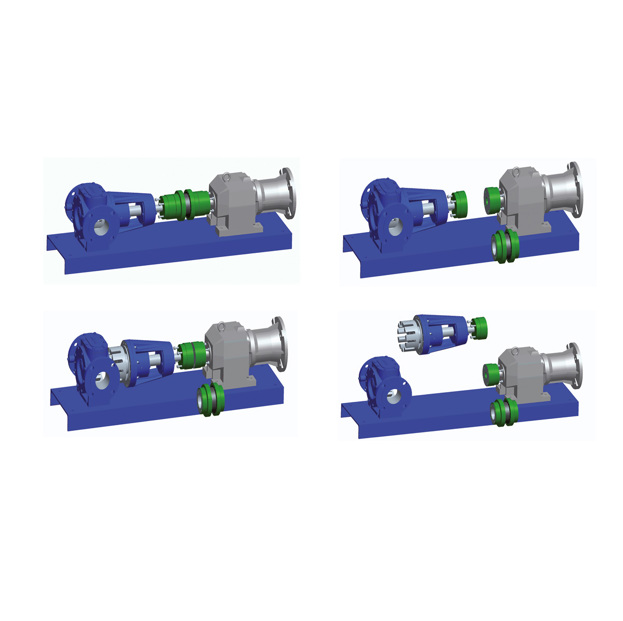

Designed for serviceability

With its true back-pull-out construction, the ROTAN® pump simplifies maintenance by allowing internal components to be accessed without disturbing piping or motor alignment. Uptime cartridges make repairs even faster - enabling offline servicing and quick reinstallation. This reduces both downtime and lifecycle costs, especially in systems where availability is critical.

Flexible to your needs

From food production to hazardous chemical handling, ROTAN® pumps are built to meet a wide range of application demands. Each pump can be tailored to the job, with configurations suited for both standard and highly specialized processes.

Choose from cast iron, carbon steel, or stainless steel to match your fluid and environment. Optional features like magnetic drive, heating jackets, and external lubrication provide application-specific flexibility. Certified configurations ensure safety and compliance, even under demanding operating conditions.

Selecting the right ROTAN® internal gear pump

The right internal gear pump depends on your fluid, application, and system demands. ROTAN® offers a full range of models tailored to specific industries - whether you're working with high-viscosity media, corrosive chemicals, or need leak-free operation.

Each model is engineered to deliver reliable, efficient performance in demanding conditions, helping you maintain uptime and control over your processes.

Explore our Product Library or use the ROTAN® selection tool to find the model that fits your needs.

Applications for ROTAN® internal gear pumps

ROTAN® internal gear pumps are used across industries where stable, pulse-free flow and high reliability are essential. Their ability to handle a wide range of viscosities - including corrosive, abrasive, and shear-sensitive fluids - makes them suitable for both standard and highly specialized applications.

Typical applications include:

-

Chemical processing – acids, alkalis, solvents, additives

-

Bitumen and asphalt – high-viscosity fluids with heating

-

Food and beverage – chocolate, syrup, oils

-

Paints, resins, polymers – low-shear transfer

-

Lubrication systems – dosing in machinery

-

Petrochemical and fuel – refined products, hydrocarbons

-

Marine and offshore – sludge, bilge water, heavy oils

Frequently Asked Questions

Are ROTAN® internal gear pumps ATEX certified?

Yes. ROTAN® internal gear pumps are certified for use in explosive atmospheres according to ATEX requirements. The pumps are approved by Physikalisch-Technische Bundesanstalt (PTB) under registration number 03 ATEX D052. This certification confirms their safe operation in environments with flammable gases, vapors, or dust. Many models in the ROTAN® range are available with ATEX-compliant configurations to meet industry-specific safety demands, particularly in chemical, petrochemical, and fuel applications. If you require documentation for a specific pump model or installation, please contact DESMI directly.

Can a ROTAN® pump replace another brand?

In many cases, yes. While not all pump geometries are identical, ROTAN® internal gear pumps are available in a wide variety of sizes and configurations that allow them to replace competitor models - especially when those pumps follow similar dimensional standards or are based on ROTAN® designs. Our team can help match the correct ROTAN® model based on performance curves, flange dimensions, flow requirements, and application constraints. This often enables reuse of existing drive equipment, helping reduce retrofit costs and downtime.

What makes internal gear pumps better for viscous liquids?

Internal gear pumps are uniquely suited for handling viscous liquids because of their positive displacement design and tight internal clearances. As viscosity increases, volumetric efficiency improves - allowing the pump to transfer thick media without significant energy loss or performance degradation. Unlike centrifugal pumps, which rely on high-speed rotation and can lose efficiency as viscosity rises, internal gear pumps operate at lower speeds with steady, pulse-free flow. This makes them ideal for applications involving asphalt, molasses, resins, heavy oils, and other high-viscosity products.

Do ROTAN® pumps support bi-directional flow?

Yes. All ROTAN® internal gear pumps are designed for bi-directional operation, meaning they can pump fluid in either direction depending on the motor rotation. From the pump shaft end, clockwise rotation will pump from right to left, while counterclockwise will reverse the direction. This feature is especially useful in systems that require fluid recirculation, tank stripping, or bidirectional transfer. If a pressure relief valve is installed, it must be positioned correctly with the spring element on the suction side relative to the selected flow direction.

How long do ROTAN® gear pumps last?

The service life of a ROTAN® internal gear pump depends heavily on the operating conditions, fluid characteristics, and maintenance practices. In optimal conditions - such as handling clean, lubricating fluids - ROTAN® pumps have been known to run continuously for over 30 years without needing major service. In contrast, applications involving abrasive particles or aggressive chemicals may require more frequent inspection and overhaul. DESMI offers expert support and spare parts to help extend the life of your pump, even in the most demanding environments.

How do I choose the right ROTAN® model?

Choosing the right ROTAN® pump model depends on several factors: fluid viscosity, chemical compatibility, temperature, flow rate, pressure, and the operating environment. The ROTAN® product line includes a wide range of pumps tailored for general duty, heavy-duty, chemical handling, and sealless applications. To simplify the process, DESMI offers a free ROTAN® selection tool that allows users to input application data and compare curves, motor sizes, and efficiency parameters. Alternatively, our technical support team can guide you through the selection process to ensure the best match for your system.