Pump energy efficiency

Facts about frequency converter and efficiency of pump

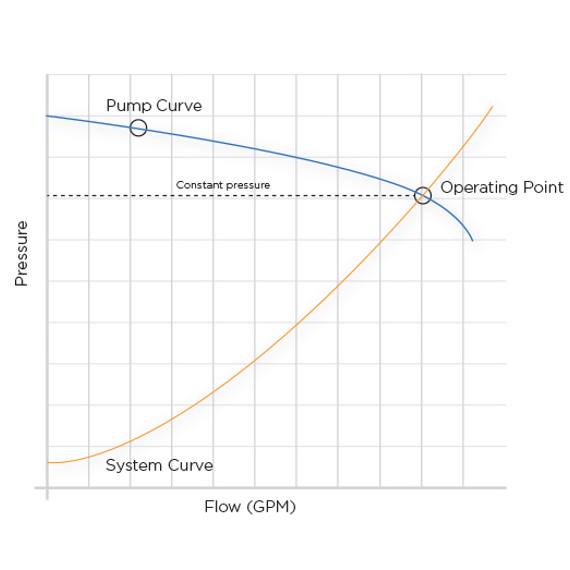

This flow is achieved but at a reduced pressure. Operating at reduced pressures results in longer pump seal life, reduced impeller wear and less system vibration and noise.

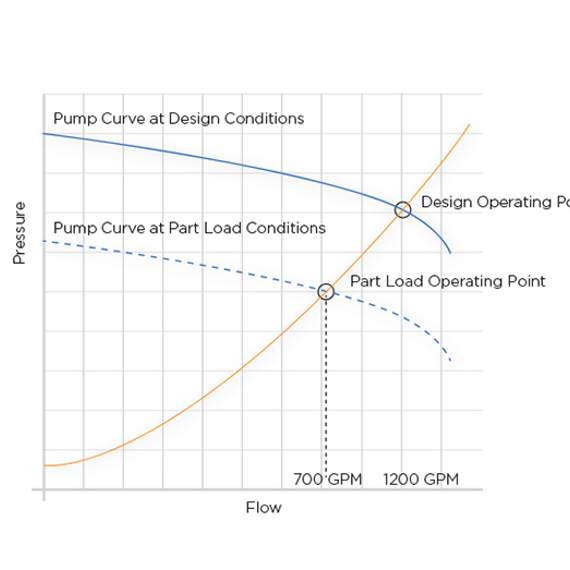

A pump without frequency control will have to be sized for the maximum flow, and then turned off occasionally when there is no need for the pump.

Each time a pump is re-started, it will take a few minutes before the performance is restored. These multiple start / stop leads to increased consumption and increased wear. With frequency control adjusts the pump's performance to the current needs without these many start / stop.

An electric motor's speed can be adjusted with the frequency converter, where electricity network 50 Hz is converted to a lower frequency - the lower the frequency, the lower the rate.

Frequency conversion allows the engine to retains it’s torque, although the speed is regulated almost down to zero. The engine can run very stable even at very low speeds and with high demands. The frequency regulation is preferable, over on/off control or voltage regulation.

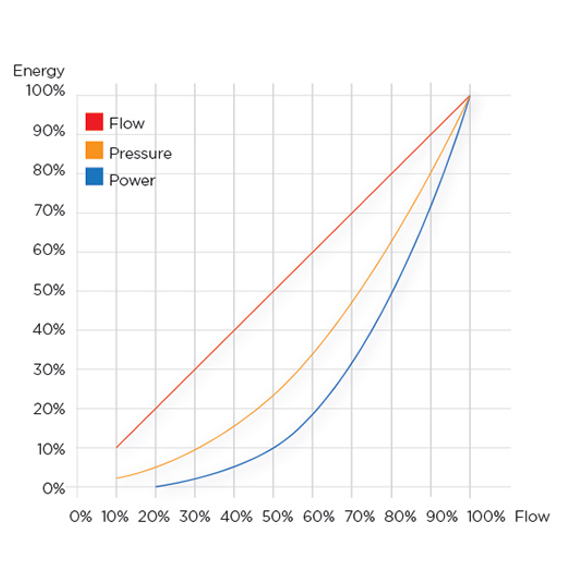

If a pump is running at say 55kW, a frequency converter can reduce the power it requires by 85%. So if a pump is running for 24 hours for 200 days this could mean energy savings worth US$20,000 or more. The potential savings are huge.

The pump runs down between 40 and 70 hertz, ensuring lower costs and the return on investment is between 12 and 18 months and can be financed from the energy savings made. Another solution could be to analyse the system and then trim it so that it fits together. A result could be to remove all orifices and trim the impeller at the pump or change the pump.

Replacing an old worn out pump to an economy pump of course require an additional investment in relation to a pump similar to the existing one, but if you looking at the pumps lifecycle, (in Denmark average is 13 years) there is no doubt that the new pump will provide both an economic benefit and save a significant CO2 emissions. For example, a new pump in a heating system for 20 apartment buildings have earned themselves back in under 5 years, compared to a conventional pump.

Improved energy efficiency Coating:

DESMI pumps can be offered with an inside coating in order to increase efficiency. The applied coating is a Chesterton ARC HT-S coating. It can increase efficiency of 3-4% if the duty point is 0,5-0,9*BEP on the curve. Max liquid temperature for this coating is 150 degrees C.

For accurate calculation of efficiency increase and price information please contact desmi@desmi.com

VFD / Variable Frequency Converter / VSD

DESMI pumps can be fitted with VFD (FC, VSD) as well. This give more options of selecting the right pump in WinPsP and therefore be able to achieve higher efficiency in the duty point and maybe a smaller and therefore cheaper pump.

Doosan is one of Korea’s foremost EPC contractors for plant projects inside or outside Korea. They fabricate, cast and compress metal materials needed by industry. Their business system creates consistency across all of Doosan’s businesses, maximizing the efficiency and driving the performance-based culture. That is exactly why DESMI were asked to conduct a survey based on the supply on DESMI NSL centrifugal pumps.

The installation of the NSL pumps from DESMI in place of previously installed pumps of another brand brought Doosan Heavy Industry the following benefits:

- A significant 35% annual energy saving in electricity costs due to more efficient DESMI pumps.

- A flow increase of 18%, due to the higher flow capacity of DESMI pumps.

- A 50% space saving, due to DESMI pumps being more compact.

- A noise reduction of approx. 15% by using the DESMI pumps.