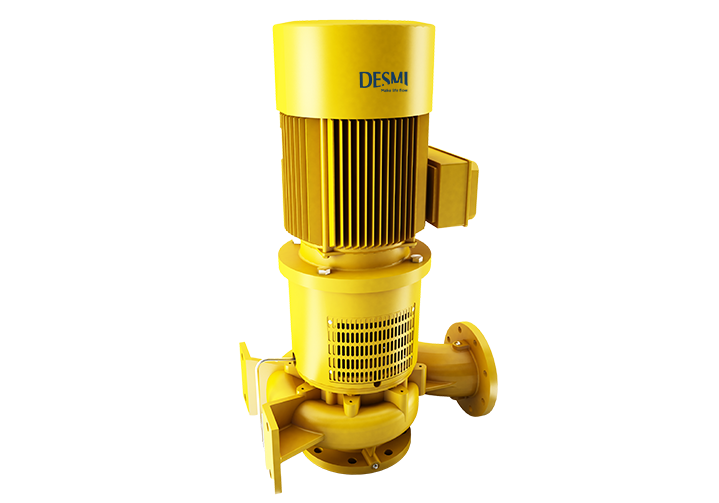

NSLV Centrifugal Pump

End suction centrifugal pump with vertical inlet

Up to 1800 m³/h (7900 US gpm)

The DESMI NSLV pumps are designed for vertical mount and meets the special marine and industrial market requirements.

- District heating/cooling

- Sea water

- Water circulation

- Cooling towers distribution

- Chiller distribution

- Diesel transfer up to 500 cSt.

- Scrubber (flue gas cleaning).

Within Aquaculture industry the pumps are suitable as:

- Freshwater

- Water with additives

- Seawater

- Oils up to 500 cSt

RAS Applications:

- Oxygen Control

- Intake Water Pumps

- Cooling/Heating Pumps

The pumps are particularly suitable for the pumping of water in connection with cooling systems, cooling of diesel engines, as bilge pumps, ballast pumps, fire pumps, brine pumps, pumps for irrigation, fish farms, water works, district heating, salvage corps, army and navy, etc.

Within the marine industry the pumps are suitable as fresh and seawater cooling pumps, bilge and ballast pumps, fire-fighting and general service pumps, and further for transport of slightly aggressive liquids with low viscosity such as diesel and lubricating oils. Further, the pumps can be supplied in a special version for pumping brine and similar media.

The DESMI NSLV & NSLH pumps is know for their:

- High efficiency

- Low NPSH values

- Easy installation/service

- Specific materials

- Compact design

- Standardized to modular design

- Outstanding hydraulic design performance

- Spacer-coupling options for easy maintenance

- Robust shaft design

- High efficiency impeller with low NPSH values

- Self-priming ability with a separate built-on priming pump

The design of the NSLH/V pumps is for medium/high flow capacities up to 1500 m³/h (6,600 US GPM) & medium head up to 150mLC. The pump may be configured as vertical or horizontally. Both versions must be radially split, single stage centrifugal pump with connecting flanges according to international standards. The design of the pump needs to include mounting with electric motors having different international flange dimensions.

Material construction of the pump casings needs to be ductile cast iron GGG40 EN1561-GJL-400/DIN1693 for plain water, which shall be able to manage a working pressure of 16 bar (tested 1,5 x working pressure). For seawater applications, the pump construction of the casing shall be RG5 bronze EN1982 CC491K/DIN17656.

The pump casing shall be equipped with a NiAlBz EN1982 CC333G/DIN17656 replaceable sealing ring. Material of the shaft shall always be of high quality duplex stainless steel AISI329/1.4460.Contruction of the pump needs to be with no bearing in pumps in order to reduce service costs.

The pump needs to be fitted with dynamically balanced impellers acc. to ISO1940/1-1986 (E) G6.3 that incorporates advanced double-curved blades to ensure low NPSH-values and high efficiency resulting in lower energy consumption and therefore lower running costs.

The construction material of the impeller shall be NiAlBz EN1982 CC333G/DIN17656 (as standard) or duplex stainless steel AISI329/1.4460 for Scrubber applications.

The seal type shall be a single acting, mechanical shaft seal, which seals off the liquid cavity at the motor shaft. The liquid temperature that the pump/seal can manage should at least be 250°F/121°C. For liquid temperature above 250°F/121°C, the seal needs to be balanced.

| Nominal diameter (DN) | 65 to 600 |

| Flow rate 50 - Hz | Up to 6200m³/h (27300 US gpm) |

| Flow rate 60 - Hz | Up to 5900m³/h (26000 US gpm) |

| Head | Up to 200 m (660 ft) |

| Pressure | Up to 25 bar (360 psi) |

| Temperature | Up to 140°C (284°F) |

| Motor | Standard and EX motors |

| VFD | Direct or Wall-mounted |

| ATEX approved | Yes |

NSLV/NSLH

- English

NSLV / NSLH (Industry)

- English

- Danish

- American

NSLV & NSLH (Utility)

- English

- French

- Dutch

- Polish

- German