The reliable solution for unsaturated Polyester Resin

Breakdowns and downtimes were no longer acceptable.

| Pumps installed up till now: | ||

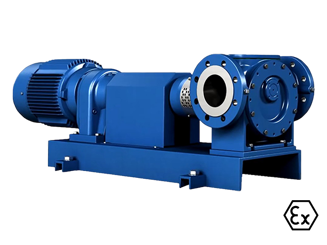

| 12 | CD 81 ERFT 3U22PAL | Keil/Tetradur/bayr.Yacht |

| 2 | CD126 ERFT 3U22PAL | Keil/Tetradur/bayr.Yacht |

| 7 | HD/PD 126 ERFT1U22PAL | Keil/Lorentz |

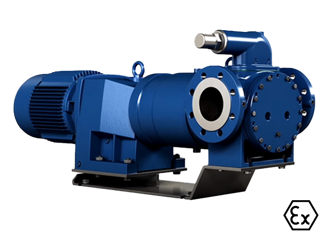

| 6 | CD81 ERFT 3U22PA | Bayrakly/Turkey |

| 3 | CD101EFT 3U22PAL | Bayrakly/Turkey |

The problem involved in pumping unsaturated resin was well-known to us. Among other things the temperature of the medium must be kept below 50°C in order to avoid coagulation. Thus it is necessary to limit the friction at the shaft seal to a minimum. Moreover, a continuous flow of the product over the shaft seal should be ensured in order to remove the heat which is inevitably generated. If a pump with a large volume and a maximum of 150 RPM was selected, internal friction in the pump would also be reduced to a minimum.

Solution

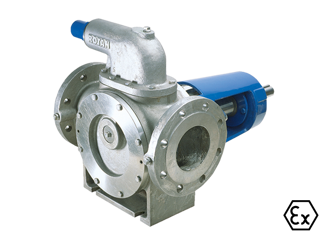

DESMI built a test pump by means of standard parts from the CD + HD/PD pump ranges with stuffing box plus 2 special, machined parts as well as 2 special shaft seal rings and a ground rotor shaft coated with tungsten carbide at the shaft seal area.

The pump was equipped with a short suction pipe from the seal housing to the suction side of the valve.

This pump, named CD81ERFT, code 3U22PAL, No. 268285, has been in intermittent duty for approx. 3-4 hours a day since the beginning of February 1997, 136 RPM x 5 bar x approx. 4000 cSt, without leakage.

Result

30 pumps of this special “PAL” design (deduced from Palatal BASF) have been delivered and put into operation.

Fields of application: Suppliers of accessories to the car industry, electrical industry, plastic industry, yacht and boat builders, wherever laminated plastic and the like are produced or used as structural member.