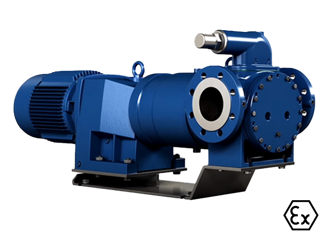

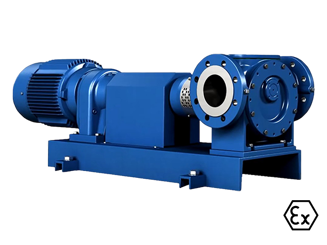

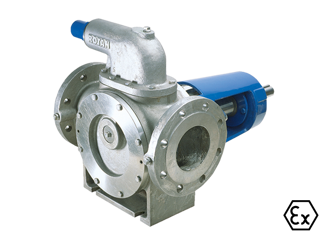

ROTAN® magnetically driven pumps

Pumping liquid tar and pitch with zero leakage and reduced maintenance.

The pumps used have to be heated and have wear resistant bearings.

Tar is often transported in ships. The pumps on board bring the tar to the storage tank from which it is pumped to the distillation towers where it is fragmented. During the process about half the tar ends up as pitch.

Pitch is among others used to produce electrodes for the aluminium industry. Normally the pitch is circulated in a ringmain by means of a 6” pump and

from the ring main the pitch is dosed by a 2” to 3” pump through a mass-flow meter to the mixers. The dosing pumps are frequency controlled.

This looks like a simple system but there are lots of details that have to be correct to avoid damage to the pumps. Koppers Denmark A/S are specialists in constructing pitch systems where ROTAN® magnetically driven pumps with bearings in solid tungsten carbide are used. ROTAN® pumps are used for these applications in Europe, South Africa and the Middle East. If you are planning to build a system where pitch has to be pumped, be sure that you involve only experienced specialists in the erection of the system.

Tar and pitch have cancerous vapour thus a seal-free pump should be used for these liquids. Both liquids are pumped at elevated temperatures and contain abrasive coke.