Pump Geared for Thin Film Evaporator

The pumps transfers the highly purified liquids from film evaporator.

Suzhou Dalong & Ningbo Dahongying Bio-Engineering & Beijing Ginko Group & Wuxi Hexiang Chemical Machinery

Separation technology is one of the three major technologies in chemical production, and the quality of the separation process has a great impact on product quality, efficiency, consumption and benefits. A film evaporator is a kind of equipment conducting the separation based on the volatility of different materials widely used for evaporation, condensation, desolventization, purification, stripping, degasification and deodorization in petrochemical, fine chemical, pesticide, food, pharmaceutical, and biological chemical industries.

Since there is always a very high vacuum level in the evaporator due to process requirements, the pump shall run with very low NPSHr together with the help of gravity of liquid itself with the pump being installed underneath the evaporator.

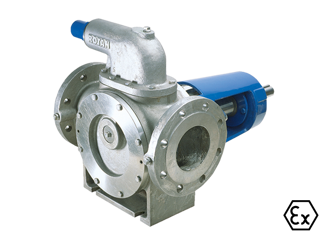

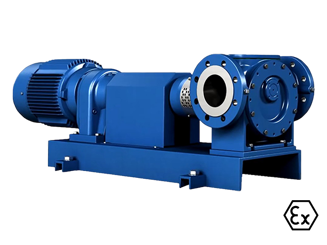

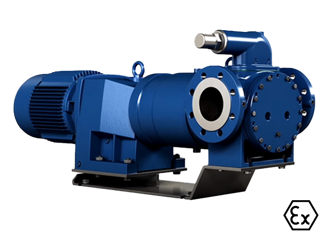

The pumps are used to transfer the highly purified liquids from film evaporator. Liquids could be lactic acid, fluid vitamin, vegetable oil or poly-glycol, kind of liquid fibre. Normally pump construction is CD26 with mechanical seal running at 500 rpm under differential pressure of 3~5 bar. The pumps are used with gearbox or equipped with Varied Frequency Driven motor.

The liquid container is under high vacuum with evaporation distillation working on top, and the gear pump shall run at low speed to bring the NPSHr down to a level below NPSHa from the system. This is majorly determined by the installation height difference (liquid flow down by self-gravity).

This is already the fifth time that Hexiang (the Thin Film Evaporator manufacturer) recommend the customers to choose or use DESMI ROTAN® gear pump, and we are glad to see this kind of strategic partnership bloom and grow.