Magnetic Driven Pumps in Molten Sulphur Service

Temperatures must be controlled within a 120-155 oC range.

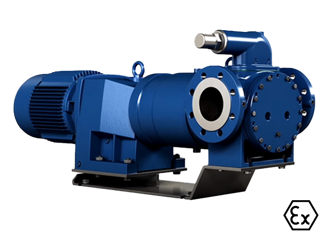

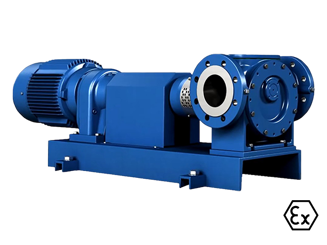

MD51EFDKR-3U88/06C with NORD SK12XZ-140TC and Reliance 2 HP, TEFC-XE motor

Pumping Molten Sulphur is most challenging. Sulphur temperatures must be controlled within a 120-155o C range. Outside this temperature sulphur solidifies.

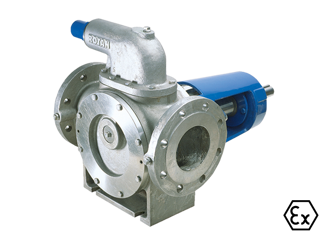

Sulphur has a distinct odour and is highly corrosive in the presence of moisture. Where leakage from common packed style pumps was unacceptable, a ROTAN® magnetically driven pump unit was offered on a trial basis where the chemical is used in the production of soap and shampoo.

Although we were concerned with sulphur solidifying and closing the internal circulating pathways, our first fully jacketed ROTAN® model MD33EFDK-1U33 proved successful. Additional sales followed among leading soap manufacturers.

Following our initial success, ROTAN® pumps have been placed in more aggressive service where sulphur is delivered under higher pressures and burned in the production of Mercaptan. Mercaptan is used as an odorant within natural gas and used in the production of plastics. In this service, stainless steel materials were required along with tungsten carbide bearings and thrust washers. Following success here, the same ROTAN® model was chosen within a sister plant operation.

Molten Sulphur is burned to produce SO2 in a process that conditions flue gas in coal burning power plants. Although small diaphragm metering pumps (.19 to .42 gpm) deliver sulphur to the process, a ROTAN® model MD101EFDK-1U33 is used to transfer sulphur from trucks and rail cars.