HOFOR Greater Copenhagen Utility

District cooling plants at: “City square” & “Adelgade/Kgs. Nytorv”.

District cooling concepts with HOFOR:

- In the winter months, production of cooling is by seawater, which is brought into the cooling system by a pipeline from the harbour. Production is totally free of CO2 emission and is called free cooling.

- The seawater is not cold enough in the summer months to cover the whole cooling demand. Therefore, surplus heat is used to produce cooling as well. This method is called absorption cooling.

- A compressor cools the seawater (as support when peak demand is very high and the capacity of surplus cooling is too low). The main part of HOFOR’s cooling production is based on “free cooling” and these compressors are only used in very high demand periods.

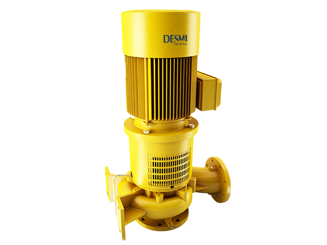

DESMI has supplied pumps for the “free cooling” part of HOFOR district cooling system. This method relies on a small amount of electricity to distribute the cooling to the customer. Furthermore, it secures a reliable delivery of cooling to the customer versus a decentralised cooling set-up. DESMI has extensive experience in seawater pumps due to supplying marine pumps for more than 100 years. DESMI has supplied pumps for the two stations HOFOR has established (The first of its kind in Denmark).

City Square Pumping Station:

- 3 DSL 300-320C/D-F + 200 kW 4 pole motor (inline pumps in bronze + duplex impeller) – Duty point 1250 m3/h, 35 m.

- 1 NSL 150-330/E02 + 75 kW 4 pole motor (inline pumps in bronze + duplex impeller) – Duty point 400 m3/h, 35 m.

- 1 NSL 100-215/E02 + 4 kW 4 pole motor (inline pump in bronze + duplex impeller) – Duty point 50m3/h, 14 m.

Adelgade (Kgs. Nytorv) pumping station:

- 6 NSLV 300-415/E02 + 160 kW 4 Pole motor (end suction pump in bronze + duplex impeller) with priming pump 114N – Duty point 625 m3/h 36 m.